|

|

GENERAL EQUIPMENT INC.

8724 Sunset Drive #191● Miami FL 33173 · USA

|

|

|

GENERAL EQUIPMENT INC.

8724 Sunset Drive #191● Miami FL 33173 · USA

|

MOBILE CONTAINER INSPECTION SYSTEM

|

TYPE: |

Inspection |

|

DESCRIPTION: |

Mobile Container Inspection System |

|

PRICE: |

Upon Request |

|

PACKING: |

Ex-Works |

MOBILE CONTAINER INSPECTION SYSTEM

1. Introduction

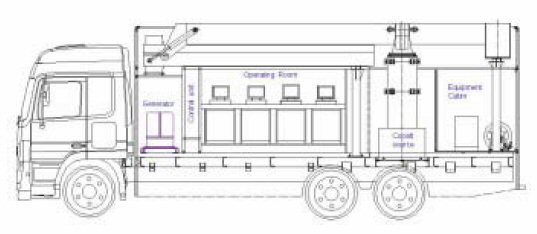

The Mobile Container Inspection System is a truck-mounted non-intrusive container inspection system with completed and advanced inspection features, excellent performance and flexible mobility.

The inspection system comprises a

cobalt-60 gamma ray source, a solid detector array, a signal and image processing subsystem, a scanning vehicle with installed scanner, a driving and control subsystem, a generator and distribution subsystem and a radiation protection and safety subsystem.All of the facilities are installed in a truck to perform efficient and high quality container inspection at different checkpoints in one port or between neighbor ports so as to detect explosives and arms for security enhancement as well as expose contrabands and drugs in smuggling or fraud.

The Mobile Container Inspection System is a highly advanced radiation imaging technology using cobalt-60 source and solid detector for screening trucks, cargo containers and passenger vehicles for contraband and explosives.

2. Technical Specifications

Gamma ray source: Cobalt-60, Activity 3.7TBq (100Ci)

Detector array: Solid detector CdWO

4 coupled silicon photodiodeWire resolution:

≤1.2mm(Copper wire) in airImage quality indicator(IQI):

≤ 3.0% (3.0mm steel wire behind 100mm steel)Contrast Indicator(CI):

≤ 1.0% (1.0mm steel wire behind 100mm steel)Maximum penetration(SP):

≥210mm steelMaximum dose per scan:

≤5μGyImage grey level: 65536

Scanning speed: 10cm/s, 20cm/s, 30cm/s, 40cm/s

Throughput: 25 containers (40ft) / hour

Size of object scanned: 2.5m(w)

×4.6m(H)×20m(L)Size of truck-mounted scanner : 10.25 m (L)

×2.5m(w) ×4.0m(H)Weight of truck with scanner: 21,500kg

Max. speed of transportation: 90km/hour

Operating temperature: -20

°C ~ +50°CRelative Humidity: 0~99%(non-condensing)

3. Construction of the inspection system

The Mobile Container Inspection System comprising:

Cobalt-60 gamma ray source device

Solid detector array (CdWO

4 coupled silicon photodiode)Signal and image processing subsystem

Scanning vehicle with installed scanner

Driving and control subsystem

Generator and distribution subsystem

4. Technical parameters of the subsystems

4.1 Cobalt-60 gamma ray source device

Cobalt-60 gamma ray source: Activity 3.7TBq(100Ci)

Source physical size:

Ф3.81×4.55mm, max.5.16mmShell of Cobalt-60 source: sealed-in double-deck stainless steel

half-life of Cobalt-60 source: 5.27 years

Energy of Gamma ray: 1.17Mev, 1.33Mev, average 1.25Mev, constant

Intensity of gamma ray: very stable during inspecting container

Packaging of Cobalt-60: all projectors meet IAEA and US, N.R.C. requirements for type B(U) packaging

Dose at surface of packaging:

≤2 μSv/h,(at 5cm from surface)Shielding case of cobalt-60: spherical case made of wolfram alloy, source located in the center of the case

Diameter of spherical case: 330mm

Source emits gamma ray spontaneously: no need to be modulated and operated

Safety shutter for intercepting radiation: made of wolfram alloy and steel

Shutter controlled by electromagnet : open when power is on, vice versa

Shutter must be closed automatically: by itself gravity when power off or accident

Time for opening or closing shutter:

≤0.5 secondSlit width of shutter: 5mm

Vertical opening angle of the slit:

≥70oFront collimator: made of steel, “L” shape, folded

Slit width of front collimator: 5mm

Shielding factor: 10

34.2 Solid detector array

Scintillation crystal of detector: Solid detector CdWO

4 (Cadmium tungsten)Photosensitive device of detector: silicon photodiode

Size of scintillation crystal: 6mm(w)

×8mm(H)×50mm(L)Detection efficiency for

γ-ray: ≥80%Space between crystals: 0.36mm

Pitch of pixel: 8.36mm

Detector modulator comprising: 16 crystals coupled 16 silicon –photodiode

Height of detector tower: Max.5.9m

Features of detector: high durability, anti-shock, moisture-proof, electromagnetic interference free

Operating temperature: -20

°C ~ +50°CRelative humidity: 0~99% (non condensing )

Electronic Circuits: preamplifier, A/D converter, DSP

Rear collimator made of steel: 100mm(W)

× 150mm(L), Height is same as detector arraySlit width of rear collimator: 8mm

4.3 Signal and image processing subsystem

The equipments comprising:

a control server: server and software

an image sampling workstation: computer and software

a supervisor workstation: computer and software

an operator workstation: computer and software

Image network: 100M Ethernet

Hardware: 160GB

Monitor: 21” color, resolution 1280

×1024Storage capacity of image database: 256GB

Image file size: 800KB~2MB

Number of images to be stored: 128,000

Interface language: in English or customized language

Functions are as follows:

Detect anomalies hidden in liquid, steel tubes, oil tanks, tires, train interlayer, chassis, cabs etc.

Differentiate liquids with different densities

Image displays synchronistically during the container is being inspected

Particular configuration can be set according to the custom’s requirements

Section zoom: 2 times, 4times, 8times, and full screen

Pseudo-color: sixteen colors shaded from blue to orange

Linear transform

Logarithm transform

Histogram equilibrium

Stripping background

Median filter

High pass filter

CAT

Absorptive shading

Pause

Customs shortcut keys

Comparison view

Cancel

Bright shading

Bright regulating

Contrast regulating

Edge enhancement

3 lens

print image and inspection report

image stored and recall

image transform

record the operator’s work state

4.4 Scanning vehicle with installed scanner

Type of chassis: VOLVO or other available truck chassis

Vehicle chassis: heavy-duty 8

×4 drive single cab chassisWeight of chassis: <7.0 tons

G.V.W: <29 tons

Dim. of transporting status: 10.25 m(L)

×2.5m(W)×4.0m(H)Dim. of working status: 10.25 m(L)

×8.5m(W)×5.0 m(H)Dim. of scanning tunnel: 3.5m (W)

×4.8 m(H)Max. speed of transportation: 90km/hr

Turning radius: 12.8m

The scanning vehicle divides into three parts:

(1). Control and image cabin:

Control subsystem, driving device, image sampling, computer, server, supervisor workstation, signal and image processing subsystem, printer, computer and monitor, air conditioned

(2). Power and distribution cabin:

Generator on board, capable of switching to shore power.

(3). Inspection equipment cabin:

Cobalt-60

γ-ray source device, front collimator, Solid detector array, rear collimator.

4.5 Driving and control subsystem:

The driving system comprising:

Power of scanning vehicle: itself engine of vehicle, engine of vehicle is turned off when inspecting container

The vehicle can be drive by a hydraulic pressure motor or electro motor

The oil of the hydraulic pressure motor is provided by hydraulic pressure pump station

The power of electro motor is provided by on board generator

The Control system comprising:

One master control system comprising a computer, several group of program logical controller position sensors, moisture sensors, temperature sensors, limit switch, two CCTV camera and monitor, one control console, photoelectric switch, one control cabinet, dose rate meter, safety interlock devices

Control system can be used to control the radiation shutter for opening and closing, to control the detector for sampling image signal or not ,to control the scanning vehicle for running or stopping, for forward or backward, to control the safety interlock devices for safety, to control the detector arm for spreading or taking

4.6 Generator and distribution:

Generator is a diesel generator

Generator and distribution cabinet are installed on the vehicle

The mobile inspection system can use either main power or the generator

Specification and photos are not contractual and are subject to verification upon inspection

TAKE NOTICE!

PLEASE BE ADVISED THAT INFORMATION INCLUDED IS CONFIDENTIAL IN NATURE AND IS BASED ON PRE-EXISTING BUSINESS RELATIONSHIP WITH THE LEGAL OWNER OF PROPERTY DESCRIBED HEREIN (IF APPLICABLE). AS SUCH, UPON RECEIPT OF SAID INFORMATION THE RECEIVER ACKNOWLEDGES THAT ANY UNAUTHORIZED CONTACT WITH SAID LEGAL SELLER WILL BE CHARACTERIZED AS A BREACH OF CONFIDENTIALITY AND SAID AGREEMENT MAY BE ENFORCED UNDER EXISTING LAW OR IN EQUITY.

This paper was prepared by

General Equipment Corp.

The paper represents an offer of a partner of General Equipment Corp.

All rights are reserved by and for General Equipment Corp..

All

content and ideas of this paper are the property of General Equipment Corp.

Defense items are subject to final destination approval and granting of an

export license issued by exporting country's authorities